Transparent supply chains are the norm for responsible companies. RethinkRebels believes transparency is the first step to transform the fashion industry because of the simple thought “If you know what’s wrong, you can change it for the better”. But why, oh why, is it so darn difficult to get transparency? Let us get down to the bottom of it…

Fashion’s complex global production network

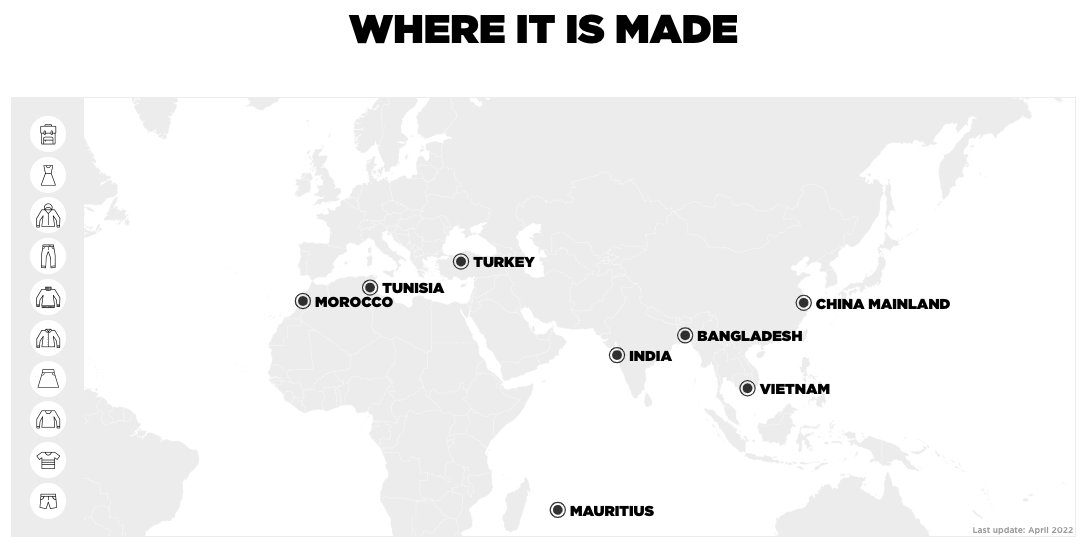

Fashion. One of the most complex global production networks. Global supply chains are opaque and consumers lack information. A simple ‘made in China’ label doesn’t say much about if the garment worker has a good job making the T-Shirt, now does it? We simply don’t know. We are increasingly disconnected from the people who make our garments. Did you know that 97% of our garments are made overseas? Feels a bit like we took ‘see nothing, hear nothing’ too literally, right? And yes, I say we. Because we all buy clothes and have a common responsibility here…

We want transparency. Bad.

There is a growing trend of global apparel companies adopting supply chain transparency. Step-by-step brands are starting to publish the names, addresses, and other important information about factories, manufacturing their branded products. For example G-Star Raw & H&M are showing this on their website already. Check out how MUD Jeans transparently communicates their sustainability efforts in their 2022 report.

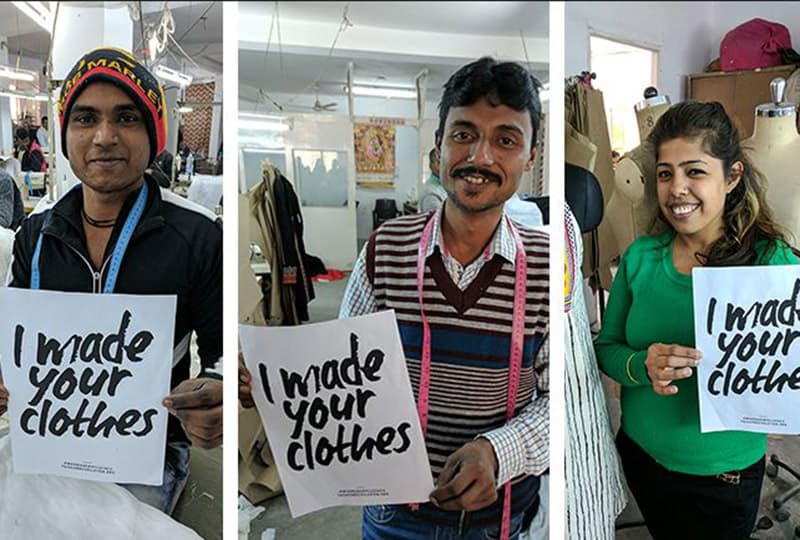

At the same time, consumer interest in transparency has increased. The conversations and comments of consumers on social media have a growing impact on the perception and the sustainability performance of fashion brands. For example, asking your favourite brand #whomademyclothes organised by Fashion Revolution. In response more companies make traceability a part of their value proposition and communication.

Source: Factories of G-Star

Transparency as tool for sustainable production

Transparency is a powerful tool for sustainable production and promoting corporate accountability for garment workers’ rights in these global supply chains. Brands and manufactures are enabled to identify challenges and risks along their supply chain. Also to get a better understanding to manage opportunities and introduce more sustainable practices. Transparency makes supply chains more efficient and enables more informed business decisions. Lastly, transparency equips companies with data which they can use for external communication and show the impact of products in a credible way.

Transparency Pledge

In 2016, 9 labor and human rights organisations formed a coalition to advocate for transparency in apparel supply chains as a first step. In 2017 the transparency pledge was signed by G-Star Raw, C&A, Zeeman and Esprit. In November 2019, 8 companies joined this pledge:

Okimono, Alchemist, Marlies Dekkers, Kings of Indigo, Kuyichi, WE fashion, Schrijvens Corporate fashion and HEMA. Yay! More to follow please.

Goal: Creating a supply chain standard

Simply said, signees promise to make their production locations known in a place that is accessible to citizens. Brands show their factories and sub-suppliers that are needed to manufacture a garment and update this regularly. By getting companies to publish standardised, meaningful information on all CMT (Cut Make Trim) factories it’s possible to create a common minimum standard for the supply chain. Each company that signs this pledge commits to these steps within 3 months of commitment:

- Full name of all authorised production units and processing facilities (processing factories include printing, embroidery, laundry, and so on)

- The site addresses.

- The parent company of the business at the site

- Type of products made (apparel, footwear, home textile, accessories)

- Worker numbers at each site (by category: less than 1000, 10001-5000, 5001-10,000, more than 10,000)

Taking it further

Overall companies are increasing visibility in the supply chain, which is good. The focus still lies mainly on the processing and garment manufacturing stages. We need to address the complete supply chain with all chains involved. Think about manufacturing including wet processing such as dying and printing but also knitting, weaving, raw material processing and production. It’s a step into the right direction. Because we believe that little achievements produce big results. We are moving in the right direction and together we are able to transform the most complex global production networks into a sustainable one. Ready for the challenge?

Check out all transparent international production locations at 'Open Apparel Registry'.

Ready to dive deeper? Have a look at Fashion Revolution’s ‘Fashion Transparency Index 2023’.

Ready to dive deeper? Have a look at Fashion Revolution’s ‘Fashion Transparency Index 2023’.

Do you want to go more in depth? Give us a call or learn more about sustainable marketing and communication in our Academy courses.