As the issue of plastic waste grows increasingly pressing, the apparel and textile supply chain is addressing it through research and innovation. Walmart noted that the pros to the use of plastic packaging have not kept up with increases in plastic production, which amounts to roughly 500 million tons annually. About 35% of Walmart’s plastic production goes to packaging, most of which is single-use and ultimately discarded.

Did you know that only 9% of plastic packaging is globally recycled?

The positive environmental effects of using sustainable products are distributed throughout the chain from producers to end users. The CO2-saving effects of, for example, bio-based products are good for everyone and not just for the user. This way, the costs and the positive environmental effects are distributed.

Greenwashing vs. Greenhushing

It’s time to communicate as clearly, informatively and transparently as possible about the plastic packaging within a circular economy. There is so much uncertainty about this subject. Much has to do with Greenwashing (appearing more green than it actually is) or Greenhushing (doing green but afraid to communicate about it). RethinkRebels believe transparency is key and with the right information, you can make the right decisions regarding packaging and communicate about it fairly.

Bio-based products are made from biomass such as sugar cane

When a product is bio-based it means that the product is made from biomass such as sugar cane or corn. The sugars are extracted from this biomass and the basic raw material ethylene can be made from this. Ethylene materials are bonded together, creating polyethylene, which is used to make plastic. Note: Ethylene materials are both made from fossil raw materials and from biomass. In this situation, the end result, plastic, is similar whether it is created from fossil or bio-based raw ingredients, and there is no loss of quality.

When a product is bio-based, you can’t just throw it into nature.

There is still a lot of uncertainty among users of bio-based products and users think that these products can be broken down in nature. But the reality is that it is a bit more complicated. Let’s look at it more in detail and inform you about the degradation possibilities of plastics.

The degradation possibilities of plastics

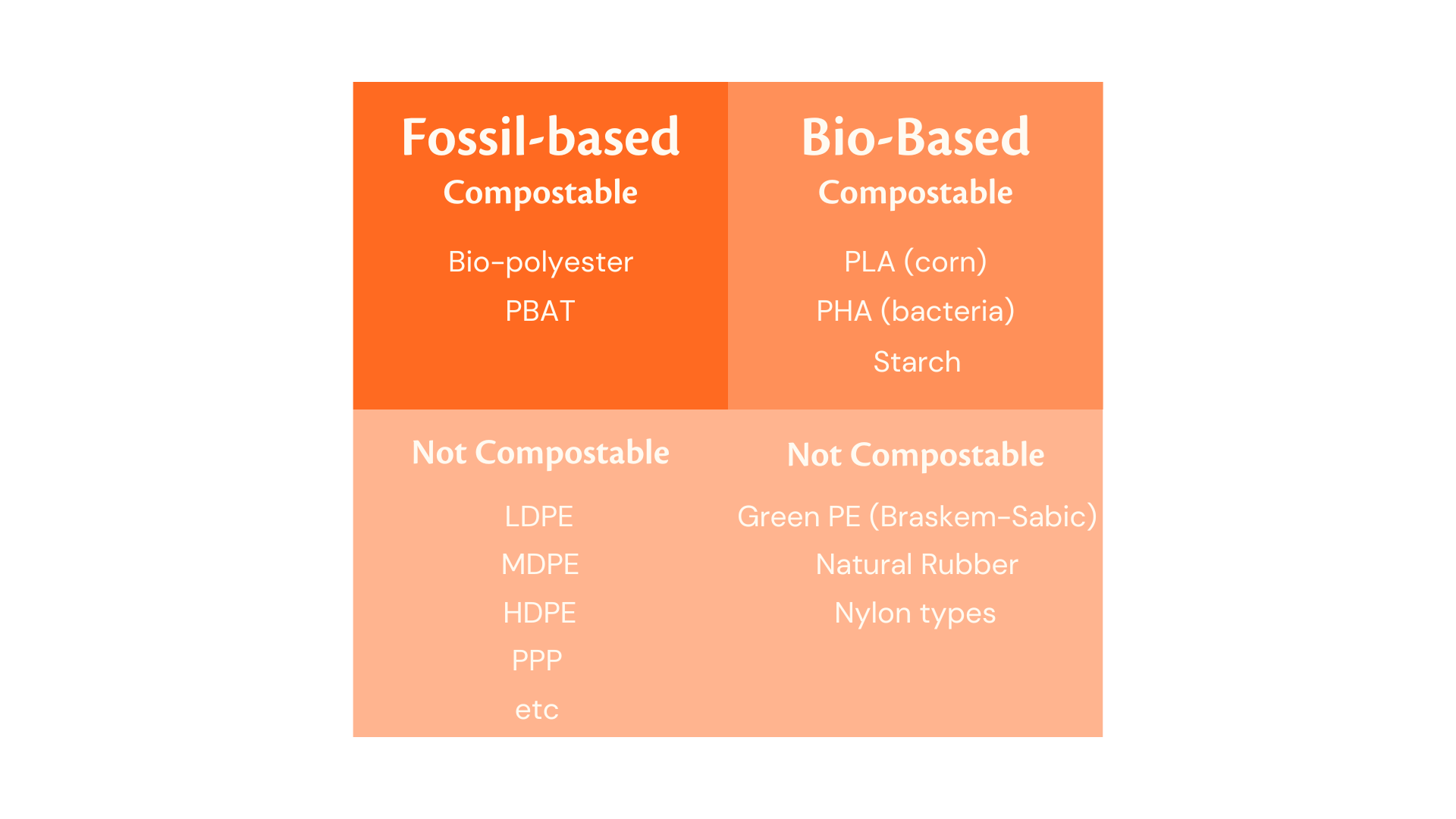

Plastics are either fossil or bio-based. Within these 2 groups, there are compostable and not-compostable kinds. Herewith a clear framework to shed some light on this:

Source: https://vendrigpackaging.com

Compostable and non-compostable fossil-based plastics

Plastic products are currently made from fossil fuels. And we all know that fossil fuels are finite and produce CO2 during the production of plastic which causes the climate to heat up. Time for innovation and time to look at better options.

A big advantage of bio-based plastics they are CO2 NEUTRAL

The big advantage of bio-based products (biomass/bioplastics) is that they have a different carbon (CO2) cycle than products made from fossil materials: during their growth cycle, they absorb CO2. Therefore these products are seen as CO2 neutral. In theory, it is, therefore, possible to make infinite biomass on earth.

Compostable vs. not compostable bio-based plastics

Bio-based plastics are also called bio-plastics. The difference here is the compostable and not compostable abilities within this group. Compostable bioplastics are either composted industrial (55-60 degrees Celsius and enzymes) or domestically composted (Green trash bin: less high degrees, time and enzymes). The not-compostable bioplastics should be recycled within regular plastic recycling. The environmental advantage here is that the raw materials are from plants and therefore take up CO2 during their growing process (indifference to fossil-based raw materials).

The packaging industry now lacks rules about what producers should put on their packaging about recyclability.

The current recycling claims on the packaging are often theoretical and can give the wrong signal. For example, packaging made of biodegradable plastic. The consumer thinks that this packaging can be composted or recycled very well. The reality shows that recycling companies are experiencing problems with the recycling of these packaging. In the end, they almost always go into the incinerator.

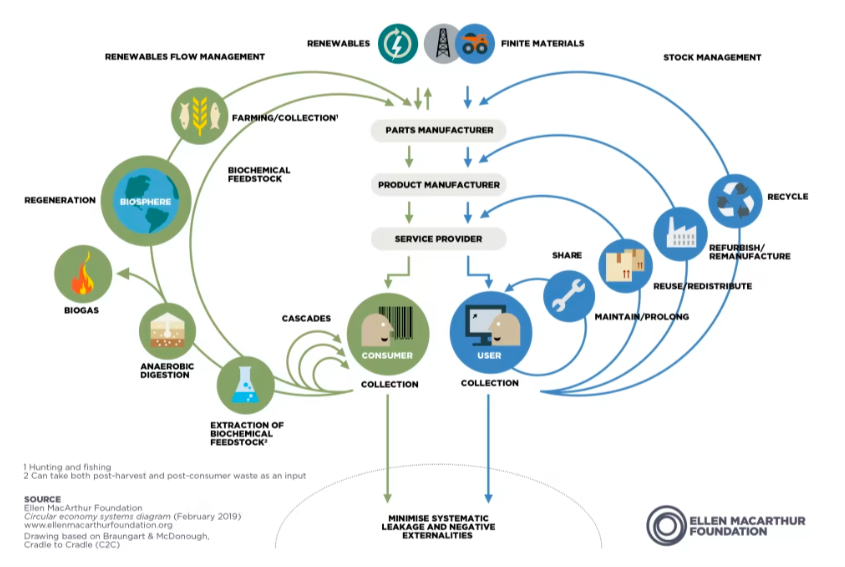

Source: Ellen MacArthur Foundation

Circular packaging model

New business models and innovations, using circular economy principles, are transforming traditional take-make-dispose thinking with incredible speed. The fashion industry should be a part of the circular economy revolution and committed to making some breakthroughs in packaging waste.

Ideal sustainable packaging should contain

- 1 sort material (partially made from recycled material)

- Optimised caps and labels that don’t disturb the recycling of the other materials

- Transparent or light colour

Source: Duurzaam bedrijfsleven

Do you want to go more in depth? Give us a call or learn more about circular business models in our Academy courses